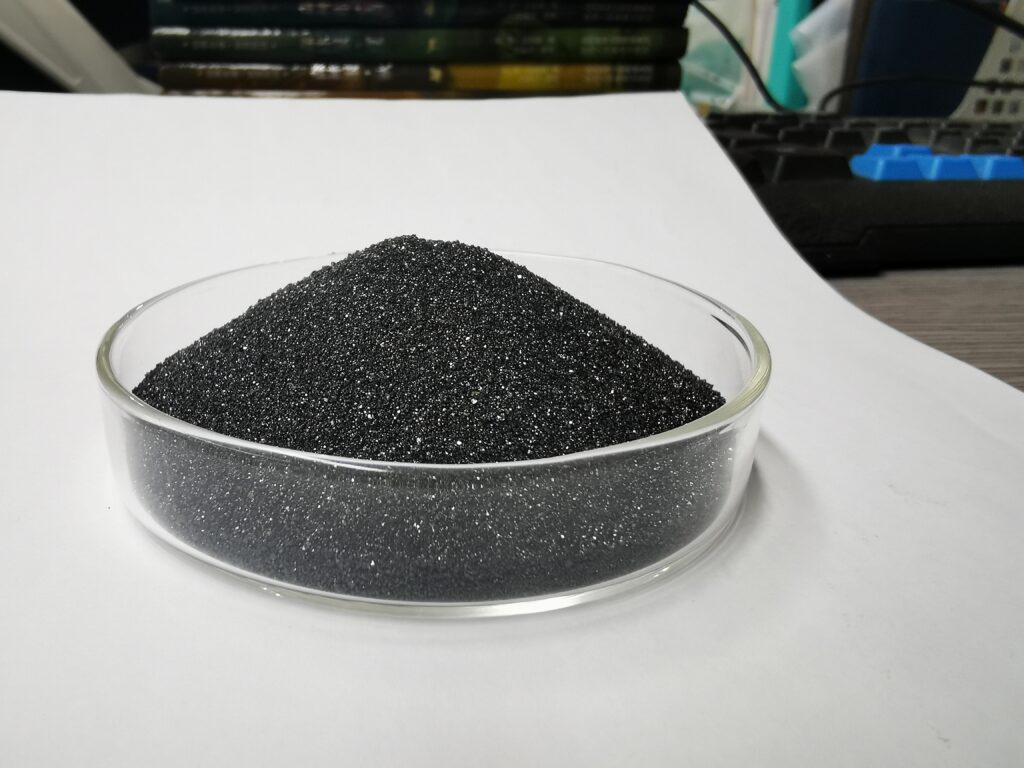

Chromite sand (FeCr₂O₄) is a premium refractory material critically important in the foundry industry for producing high-quality wear-resistant hammers and other abrasion-resistant parts, typically made from High Manganese Steel (Hadfield Steel, e.g., ZGMn13) or High-Chromium Iron.

Its use is not for the entire mold but as a strategic facing material to solve specific problems inherent in casting these challenging alloys.

| Item | Unit | Index |

| Cr2O3 | % | 46.0min |

| SiO2 | % | 1.0max |

| FeO | % | 26.5max |

| CaO | % | 0.30max |

| MgO | % | 10.0max |

| Al2O3 | % | 15.5max |

| P | % | 0.003max |

| S | % | 0.003max |

| Cr/Fe | / | 1.55:1 |

| Bulk Density | g/cm3 | 2.5-3 |

| Color | / | Black |

| PH | / | 7-9 |

| The amount of the acid | / | 2ML(MAX) |

| Percent Soil | % | 0.1max |

| Percent Moisture | % | 0.1max |

| The Sintered | 1600 | |

| Percentage of Free Acid Present in the Sand | % | 0 |

| Filling Density | g/cm3 | 2.6 |

| Sintering Point | 1800min | |

| Melting Temperature | 2180 |

Why is Chromite Sand Essential for Wear-Resistant Hammers?

Wear-resistant hammers are subject to extreme impact and abrasion. To achieve this, they are cast from alloys that are exceptionally demanding on the foundry process:

Very High Pouring Temperatures: Often exceeding 1500°C (2732°F).

High Metal Oxide Activity: Alloys rich in manganese (Mn) and chromium (Cr) are highly reactive in their molten state.

High Shrinkage: These alloys contract significantly upon solidification, creating stress on the mold.

Chromite sand advantages:

Exceptional Refractoriness: With a melting point above 1850°C (3362°F), it remains solid and dimensionally stable at the pouring temperatures of wear-resistant steels.

High Resistance to Metal Oxide Penetration: It is chemically neutral or basic, making it highly resistant to the acidic slags (e.g., MnO) formed during casting. This prevents chemical burn-on and reaction at the metal-mold interface.

Low Thermal Expansion: It expands very little when heated, significantly reducing the risk of veining or cracking in the mold, thereby preventing mechanical penetration of metal.

Excellent Thermal Conductivity: It draws heat away from the casting surface faster than silica sand. This promotes:

Finer Grain Structure: Faster cooling leads to a finer metallurgical grain structure at the surface, which can enhance surface hardness and wear properties.

Better Dimensional Accuracy: Reduces the time the metal surface remains liquid, minimizing penetration.

High Puncturing Resistance: Its high density and hardness make the mold surface more resistant to erosion when the molten metal stream hits it, preserving the mold’s shape.

How is Chromite Sand Used in the Casting Process?

As a Facing Sand:

A layer of chromite sand, typically 20-100 mm thick, is placed against the pattern to form the mold cavity surface that will contact the molten metal.

The remainder of the mold (the backing sand) is filled with cheaper silica sand or olivine sand.

This method provides all the benefits of chromite directly where it’s needed most.

As a Core Sand:

For complex core geometries that are difficult to clean, using chromite sand ensures the sand does not fuse to the internal surfaces of the casting.

In Paints and Coatings:

Chromite sand is milled into a fine powder and used as the primary refractory aggregate in mold and core washes (coatings).

A slurry of chromite powder, a carrier (e.g., water or alcohol), and binders (e.g., zircon flour, resins) is sprayed or brushed onto the surface of a mold made from ordinary sand.

This creates a dense, highly refractory barrier layer. This is a very cost-effective way to utilize chromite’s properties.