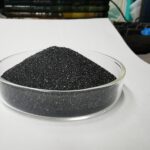

325mesh chromite flour application

325-mesh chromite flour is a premium, performance-enhancing material used primarily as a refractory coating in steel foundries to achieve superior casting surface quality and as a fine aggregate in advanced refractory bricks and monolithics for high-temperature industrial furnaces.