Comparing with silica sand,chromite sand can avoid most sand stick on the casting,therefor it can also save cost to make surface treatment. Moreover,chromite can be recycle used for several times upon to different technology.

THE APPLICATION

Chromite sand‘s’ properties enable the material to be used in high duty grey iron and steel foundries as core and mould making sand. Its high thermal conductivity gives it good chilling properties, low thermal expansion gives rise to good dimensional stability. Itsbasicity being close to neutral allows the use of a wide range of resin bonding systems and inorganic binders, it has a high refractoriness and a broad sieve distribution.

Chromite sand is suitable for steel casting including foundry such as:

Less than 500KGS | 500-1000KGS | 1-10 Tons | 10-30 Tons | 30-100 Tons |

AFS40-70 | AFS 45-50 | AFS 45-50 | AFS40-45 | AFS 35-40 |

CHEMICAL COMPOSITION | |

Cr2O3 | ≥46.0% |

SiO2 | ≤1.0% |

FeO | ≤26.5% |

CaO | ≤0.3% |

MgO | ≤10% |

AL2O3 | ≤15.5% |

P | ≤0.003% |

S | ≤0.003% |

Cr/Fe | 1.55:1 |

TYPICAL PHYSICAL PROPERTIES | |

Hardness: | Mohs:5.5-6 |

Melting Point: | Sublimes at 2180 ℃ |

Sintering point: | >1800℃ |

The sintered | 1600℃ |

Specific Gravity: | 4.0-4.8 g/cm3 |

Bulk density(LPD): | 2.5-3 g/cm3 |

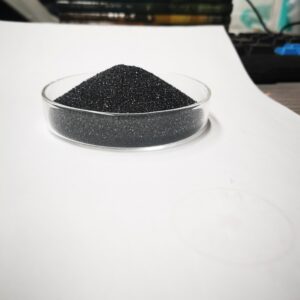

Color: | Black |

PH | 7-9 |

Percentage of free acid present in the sand | 0% |

The amount of the acid | ≤2ML |

Percentage of soil | ≤0.1 |

Percentage of Moisture | ≤0.1 |

AVAILABLE SIZES | |

AFS15-20,AFS15-25,AFS25-35,AFS25-30,AFS30-35,AFS35-40,AFS40-45,AFS45-50,AFS40-50,AFS50-55,AFS55-60,AFS60-65 customized sizes are available upon request | |